Fathom Nickel Intersects Rottenstone-Like Nickel Tenor in Drillhole AL24077 at Albert Lake Project

Calgary, Alberta–(Newsfile Corp. – April 16, 2024) – Fathom Nickel Inc. (CSE: FNI) (FSE: 6Q5) (OTCQB: FNICF) (the “Company” or “Fathom“) is pleased to announce results of the Q1 drill program at the Company’s 100% owned Albert Lake Project. Additionally, effective April 8, 2024, drilling has been completed at the Gochager Lake Project. Assays for the Gochager Lake project are expected to be released by the end of May.

Highlights of Q1 Albert Lake Project drill program:

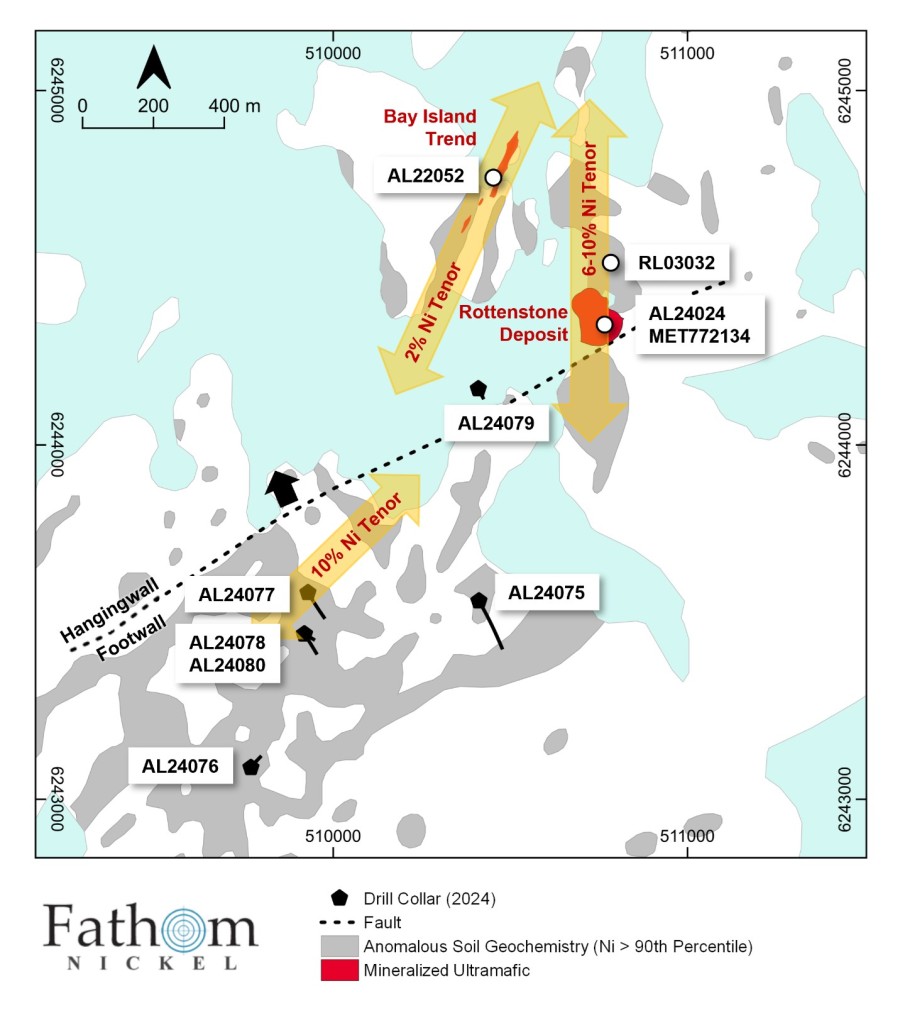

- Six (6) drillholes (AL24075 – AL24080), totaling 1,386 meters drilled at the project (Figure 1, Table 1).

- Drillhole AL24077 intersected 0.42% Ni over an intersection of 2.01 meters (Table 2).

- Importantly, this nickel mineralization is hosted in orthopyroxenite. Orthopyroxenite is part of the host rock assemblage recognized at the historic, and very high-grade Ni-Cu+PGE Rottenstone deposit located approximately 1.2 kilometers to the northeast of AL24077 (Figure 1).

- Also of importance, the AL24077 nickel intersection has a very high nickel tenor (~10%). Typical Rottenstone mineralization has a nickel tenor of in the 6-10% range (see Table 3, Figure 1).

- Shallow off-hole BHEM conductivity anomalies were detected in all drillholes surveyed.

Ian Fraser, CEO and VP Exploration stated, “The elevated nickel concentration in Rottenstone-like ultramafic rock and the very-high associated nickel tenor identified in our drillhole AL24077 is a very significant development. We recognize high nickel tenors associated with Rottenstone-type mineralization and in ultramafic rock occurring along strike and in the structural trend that hosts the historic Rottenstone deposit / mine. The 10% nickel tenor defined in intervals comprising <3% sulphide in drillhole AL24077 indicates that net-textured to massive sulphide mineralization occurring along strike, and most likely at depth, within this same ultramafic unit could develop into a mineral deposit with metal grades similar to the historic Rottenstone deposit. We think the robustness and size of the multi-element soil geochemistry anomaly around AL24077 indicates chemical contributions from a large mineralized ultramafic body in the footprint of this soil geochemistry anomaly. The Company plans to further evaluate this robust soil geochemical anomaly by undertaking detailed surface geochemistry and geophysics to reconcile soil geochemistry with surface and BHEM anomalies. Understanding the coincident geochemical and geophysical responses coincident with the ultramafic stratigraphy in AL24077 will help guide the next phase of drilling. A nickel tenor of 6-10% is a feature of the Rottenstone Deposit which carried exceptionally high nickel grades. Identification of high nickel tenor 1.2 km south of historic Rottenstone, and within the multi-element soil anomaly is another very significant clue in our quest to discover a large nickel deposit with Rottenstone-like grades. More work is required; however, this is another important development at the Albert Lake project. We are getting closer.”

Figure – 1 Albert Lake Project Drillhole Plan Map

Figure – 1 Albert Lake Project Drillhole Plan Map

Table – 1 Drillhole Location Summary

| Drillhole | Easting* | Northing* | Azimuth (°) | Dip (°) | Final Depth (m) |

| AL24075 | 510411 | 6243560 | 150 | -70 | 401 |

| AL24076 | 509767 | 6243090 | 40 | -79 | 212 |

| AL24077 | 509928 | 6243583 | 148 | -68 | 209 |

| AL24078 | 509918 | 6243467 | 150 | -72 | 218 |

| AL24079 | 510409 | 6244158 | 148 | -80 | 200 |

| AL24080 | 509917 | 6243466 | 120 | -77 | 146 |

* Drillhole locations are UTM NAD83 – Zone 13.

Table – 2 Drillhole Assay Summary

| Drillhole | From (m) | To (m) | Interval (m)* | Ni wt% | Cu wt% | Co wt% | 3E g/t** |

| AL24075 | 333.81 | 338.66 | 4.85 | 0.02 | 0.03 | 0.003 | 0.03 |

| AL24076 | No significant results | ||||||

| AL24077 | 25.44 | 27.45 | 2.01 | 0.42 | 0.06 | 0.013 | 0.18 |

| Including | 25.79 | 26.09 | 0.30 | 0.93 | 0.12 | 0.028 | 0.11 |

| AL24078 | 72.76 | 78.68 | 5.92 | 0.02 | 0.002 | 0.004 | 0.02 |

| AL24079 | 156.50 | 158.30 | 1.80 | 0.03 | 0.07 | 0.004 | 0.03 |

| AL24080 | 129.8 | 130.8 | 1.00 | 0.09 | 0.004 | 0.009 | 0.03 |

* Interval is not true thickness. Insufficient data currently to determine true thickness.

** – 3E is palladium + platinum + gold.

Comments on Individual Drillholes:

AL24075 – Drilled to test the source of very strong TDEM (conductivity) response, modelled to be more than 400m in strike and up to 100m in width, at a depth >300m below surface. The conductor is located on the eastern flank of the very robust soil geochemical anomaly and is coincident with a gravity inversion believed to correspond to a body of denser rock also at depths >300m. AL24075 determined the source of conductor to be sulphidic metapelite and sulphidic silicate-rich metasedimentary rocks containing up to 50% barren sulphides; primarily pyrrhotite + pyrite. These mineralized metasedimentary rocks, referred to as sulphidic iron formation, occur at 295-348.5m. Within this interval, weak nickel mineralization occurs at 333.81-338.66m (Table 2). This is not magmatic nickel sulphide mineralization. The hole ended in silicate rich metasedimentary rock at 401m depth. Due to caving in the drillhole, a BHEM survey was unsuccessful.

AL24076 – Drilled to test a smaller, circular, near surface TDEM conductor. The drillhole intersected metasedimentary rocks with no significant mineralization and the drillhole was stopped at 212m. The source of surface TDEM conductivity was not explained by this drillhole. However, the BHEM data for this drillhole indicates a near miss. Flat-lying conductive features were established immediately off-hole within 15m of surface. The source of this conductive anomaly requires further drilling.

AL24077 – Drilled to test very anomalous soil geochemistry coincident with subtle conductive features identified in the TDEM survey. At 25.44-27.45, the drillhole intersected weakly mineralized ultramafic rock and pegmatite (see Table 2). The ultramafic rock is typical of the rock type occurring at the historic Rottenstone deposit. The remainder of drillhole comprised largely metasedimentary rock, and the drillhole was stopped at 209m. A BHEM survey detected an off-hole conductive feature at 60-70m. The source of this anomaly has not yet been tested by drilling, nor has the continuation along strike of the mineralized ultramafic interval occurring at 25.44-27.45m.

AL24078 – Designed to drill below a surface gossan within an area of highly anomalous soil geochemistry. A mafic unit interpreted to be gabbro was intersected at 72.7-78.8m (see Table 2). The drillhole was dominated by metapelite and metasedimentary rock and no other zones of mafic-ultramafic stratigraphy were intersected. The hole was stopped at 218m. A BHEM survey detected an off-hole response 65-75m coincident with mafic unit occurring at 72.7-78.8m and an in-hole response indicating continuation beyond the drillhole occurs at a depth of 120m. At 126.1-128.1m mineralized metapelite was encountered, consisting of ~10% pyrrhotite-chalcopyrite-pyrite as stringers and disseminations.

AL24079 – Drilled from ice and designed to test a magnetic feature trending from the historic Rottenstone deposit towards the southwest. The drillhole encountered metapelite and metasedimentary rock and was stopped at 200m. A BHEM survey detected an off-hole anomaly at 180m and a building conductive signal towards the bottom of the drillhole. The source of this conductive feature has not yet been tested.

AL24080 – Designed to follow up on BHEM conductors defined from drillhole AL24078. The drillhole consisted of metapelite and granitized metasedimentary rock. A thin section of mafic-ultramafic rock was intersected at 129.8-130.8m containing minor amounts of pyrrhotite mineralization as stringers (see Table 2). Off-hole BHEM conductive anomalies were detected at ~85m and at ~135m depth. The sources of the BHEM conductors detected in AL24078 and AL24080 have not been further tested by drilling.

A full interpretation of the BHEM results is pending, but the Company is encouraged by the presence of multiple near surface BHEM conductors. Detailed surface infill geochemistry along with tighter, detailed surface TDEM will further fine tune these targets.

Table – 3 Nickel Tenor Calculations (see Figure 1 for locations)

| Drillhole / sample | From (m) | To (m) | Interval (m)* | Ni wt% | Cu wt% | Co wt% | 3E g/t** | S wt% | Ni Tenor wt%*** |

| AL24077 | 25.44 | 26.37 | 0.93 | 0.72 | 0.10 | 0.02 | 0.28 | 2.59 | 10.17 |

| RL03032 | 77.2 | 78.7 | 1.5 | 0.78 | 0.12 | 0.02 | 0.90 | 2.81 | 10.35 |

| MET772134 | Rottenstone Met Sample | 4.04 | 1.40 | 0.09 | 9.89 | 14.60 | 10.07 | ||

| AL22052 | 99.03 | 102.57 | 3.54 | 1.09 | 0.42 | 0.07 | 0.75 | 15.29 | 2.82 |

| AL21024 | 5.71 | 11.41 | 5.70 | 1.28 | 1.10 | 0.04 | 5.21 | 7.32 | 6.59 |

* – Interval is not true thickness.

** – 3E is palladium + platinum + gold.

*** – Nickel tenor is defined as the calculated nickel concentration in 100% sulphides and note in the case above to calculate Ni tenor a minimum assay of 1% S is required together with the evidence that the mineralization comprises a magmatic assemblage of pyrrhotite, pentlandite, and chalcopyrite.

Comment on Nickel Tenor (see Figure 1 for drillhole and sample locations, Table 3 for calculations):

- AL24077 – The high nickel tenor (10.17%) calculated for the ultramafic intersection in hole AL24077 is based on the significant nickel concentration (0.932%) observed in an interval containing small amounts of sulphide mineralization (S concentration of 3.4%).

- RL03032 – Historic drillhole RL03032 also contains a sulphide interval with high nickel tenor (10.35%) and small amounts of sulphide mineralization (2.81% S). RL03032 was collared ~125m north of the historic Rottenstone mine and one can interpret the thin band of ultramafic hosted mineralization as an apophysis of the adjacent high nickel tenor Rottenstone Deposit to the south. The elevated nickel tenor in AL24077 is interpreted to also be a strong indicator of a proximal ultramafic intrusion with elevated nickel tenor.

- MET772134 – The MET772134 sample is the head grade obtained from a 23kg sample of net-textured Rottenstone mineralization that Fathom submitted for metallurgical testing in 2017. This sample has a calculated nickel tenor of 10.07%. Note nickel tenors for AL24077 and RL03032 (10.17% and 10.35% respectively) discussed above. The MET sample returned: 4.04% Ni, 1.40% Cu, 0.09% Co, 9.89 g/t 3E with a S concentration of 14.6%.

- Bay Island Trend – It is also interesting to note calculated nickel grade and low nickel tenor at the Company’s Bay-Island Trend discovery; where 300+ meters strike length of ultramafic-hosted mineralization was previously reported by Fathom (see AL22052, Table 3, Figure 1). The mineralized interval 99.03-102.57m in drillhole AL22052 returned 1.09% Ni with a S concentration of 15.29% and note the low nickel tenor of 2.82%. The Rottenstone MET sample has similar contained S (14.6%) but the AL22052 intersection yielded ~ 1/3rd of the nickel grade of MET772134 (1.09% Ni vs. 4.04% Ni) and yet the host rock and mineralogy are very similar.

- AL21024 – Drillhole AL21024 was collared south of the Rottenstone Deposit indicating that the Rottenstone mineralization continues to the south. The associated nickel tenor is 6.59%.

Together with other exploration methodologies that Fathom utilizes, nickel tenor can also be used as a vectoring tool. Higher nickel tenors in the Rottenstone area coincide with elevated nickel, copper, cobalt and 3E grades. The high nickel tenor in AL24077 encourages further drilling to investigate the possibility of a larger body of ultramafic rock with net-texture to massive sulphide mineralization occurring along strike, and in the root of this system. This possible system occurs beneath a robust surface geochemical anomaly, coincident with a NE-SW trending major gravity ridge, and multiple TDEM and BHEM anomalies. This is a high priority target for further exploration.

Comment on Couloir Capital Ltd. (Couloir) Research Coverage

Fathom has engaged Couloir Capital Ltd. (“Couloir”) to provide research coverage of the Company. A Couloir press release issued on April 3, 2024, announcing this arrangement, contained certain misleading information that we feel is in need of clarification:

- Fathom’s 2-tranche financing that closed in Dec. 2023 and Feb. 2024, totaling approximately $4.5M raised, was sufficient to complete the Company’s H1 exploration programs at the Albert Lake and Gochager Lake projects and add approximately $1 million working capital to the Company’s treasury.

- The new exploration permit application for the Gochager Lake project, submitted to the Saskatchewan Ministry of Environment on January 19, 2024, is under review. The application indicates and requests that the Company will drill up to 15,000 meters at the Gochager Lake project. To facilitate this anticipated and future drilling additional exploration, the Company will establish a 20-25-person camp on the Gochager Lake property.

Fathom apologizes for the confusion this may have caused. Fathom has also requested that Couloir edit and correct the original research document from which the press release information was drawn. Couloir has complied with this request and has now posted the revised version on its website. Fathom would like to thank Couloir for their cooperation in rectifying this matter.

Quality Assurance / Quality Control (QA/QC) Disclosure Statement

Fathom implements an industry-standard QA/QC for all field and diamond drill programs. Fathom, through the services of TerraLogic Exploration Inc., inserts QA/QC samples in its diamond drill programs at a rate of one sample per approximately every 12-13 samples collected. Standards sourced from CDN Resource Laboratories and CCRMP were inserted into the sample stream at a rate of 1 in 30 samples. Additionally, lab duplicates (coarse rejects) were inserted and positioned in the sample sequence at a rate of 1 in 30 samples and positioned in the sample sequence alternating with standards to result in a QA/QC insertion rate of no less than 1 in 15 samples. Blanks were inserted at the start of every sample batch and additionally after samples of anticipated high-grade or high sulphide content.

Assaying is performed at ALS Canada Ltd. (“ALS”). ALS is an accredited laboratory (SCC – CAN-P-1579 and CAN-P-4E ISO/IEC 17025) and is independent of Fathom. All drill core samples are analyzed using a 4-Acid digestion followed by 33 element ICP-AES analyses (Code ME-ICP61). Over limit Ni, Cu results are further analyzed by 4-Acid ore grade elements ICP-AES process (Code ME-OG62). Analyses for Au, Pd and Pt utilized the ore grade Pt, Pd and Au by ICP-AES (Code PGM-ICP27). Total sulphur is analysed by (S-IR08).

Qualified Person and Data Verification

Ian Fraser, P.Geo., CEO, VP Exploration, and a Director of the Company and the “qualified person” as defined by National Instrument 43-101, has verified the data disclosed in this news release, and has otherwise reviewed and approved the technical information in this news release on behalf of the Company.

About Fathom Nickel Inc.

Fathom is an exploration company that is targeting magmatic nickel sulphide discoveries to support the rapidly growing global electric vehicle market.

The Company now has a portfolio of two high-quality exploration projects located in the prolific Trans Hudson Corridor in Saskatchewan: 1) the Albert Lake Project, a 90,000+ hectare project that was host to the historic and past producing Rottenstone deposit (produced high-grade Ni-Cu+PGE, 1965-1969), and 2) the 22,000+ hectare Gochager Lake Project that is host to a historic, NI43-101 non-compliant open pit resource consisting of 4.3M tons at 0.295% Ni and 0.081% Cu2

1 – The Saskatchewan Mineral Deposit Index (SMID#0950) Tremblay-Olson Ni-Cu Deposit or Showing

2 – The Saskatchewan Mineral Deposit Index (SMID#0880) reports drill indicated reserves at the historic Gochager Lake Deposit of 4,262,400 tons grading 0.295% Ni and 0.081% Cu mineable by open pit. Fathom cannot confirm the resource estimate, nor the parameters and methods used to prepare the reserve estimate. The estimate is not considered NI43-101 compliant and further work is required to verify this historical drill indicated reserve.

ON BEHALF OF THE BOARD

Ian Fraser, Chief Executive Officer and Vice-President, Exploration

1-403-650-9760

Email: [email protected]

or

Doug Porter, President & CFO

+1-403-870-4349

Email: [email protected]

Forward-Looking Statements:

This news release contains “forward-looking statements” that are based on expectations, estimates, projections and interpretations as at the date of this news release. Forward-looking statements are frequently characterized by words such as “plan”, “expect”, “project”, “seek”, “intend”, “believe”, “anticipate”, “estimate”, “suggest”, “indicate” and other similar words or statements that certain events or conditions “may” or “will” occur, and include, without limitation, statements regarding intended future exploration work, including drilling, and the timing of such activities. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be “forward-looking statements.” Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation: risks related to failure to obtain adequate financing on a timely basis and on acceptable terms; risks related to the outcome of legal proceedings; political and regulatory risks associated with mining and exploration; risks related to the maintenance of stock exchange listings; risks related to environmental regulation and liability; the potential for delays in exploration or development activities or the completion of feasibility studies; the uncertainty of profitability; risks and uncertainties relating to the interpretation of drill results, the geology, grade and continuity of mineral deposits; risks related to the inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; results of prefeasibility and feasibility studies, and the possibility that future exploration, development or mining results will not be consistent with the Company’s expectations; risks related to commodity price fluctuations; and other risks and uncertainties related to the Company’s prospects, properties and business detailed elsewhere in the Company’s disclosure record. Such forward looking statements involve known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements. These forward-looking statements are made as of the date hereof and the Company does not assume any obligation to update or revise them to reflect new events or circumstances except in accordance with applicable securities laws. Actual events or results could differ materially from the Company’s expectations or projections.

NOT FOR DISTRIBUTION TO UNITED STATES NEWSWIRE SERVICES OR FOR DISSEMINATION IN THE UNITED STATES. ANY FAILURE TO COMPLY WITH THIS RESTRICTION MAY CONSTITUTE A VIOLATION OF U.S. SECURITIES LAWS